Custom inductor manufacturer tells you

The inductance ferrite ring is divided into mn-Zn ferrite ring and Ni-Zn ferrite ring. According to the materials used, the calcined materials are different. Nickel-zinc ferrite magnetic rings are mainly made of oxides or salts of iron, nickel and zinc and are made by electronic ceramic process. Manganese-zinc ferrite rings are made of oxides and salts of iron, manganese and zinc, and are also made by electronic ceramic technology. They are basically the same in material and process, the only difference is that manganese and nickel are different. It is these two different materials that have very different effects on the same product.

Mn-Zn materials have high permeability, while Ni-Zn ferrites have low permeability. Mn-Zn ferrites can be used in applications where the operating frequency is lower than 5MHz. Ni-Zn ferrites have high resistivity and can be used in the frequency range from 1MHz to hundreds of MHz. With the exception of common-mode inductors, the impedance of mn-Zn materials makes it the best choice for applications below 70MHz, while Ni-Zn materials are recommended for applications ranging from 70MHz to hundreds of gigahertz. Manganese-zinc ferrite rings are generally used in the frequency range from kilohertz to megahertz. Can make inductors, transformers, filter cores, magnetic heads and antenna rods. Ni-Zn ferrite rings can be used to make cores of medium-cycle transformers, magnetic heads, short-wave antenna rods, tuned inductance reactors and magnetic saturation amplifiers. The application range and product maturity of Ni-Zn ferrite rings are much better than those of mn-Zn ferrite rings.

How do you distinguish between two cores when they are mixed together?

1. Visual method

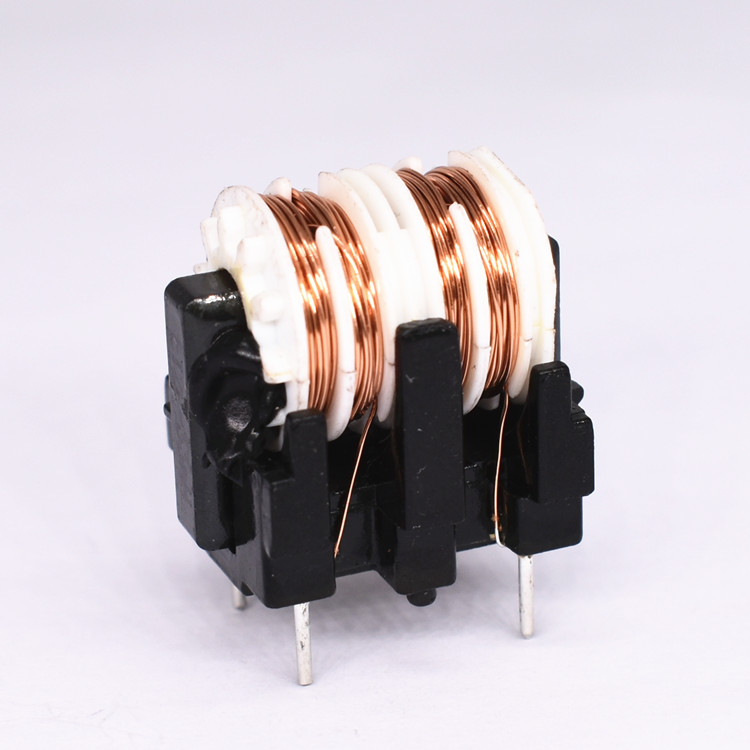

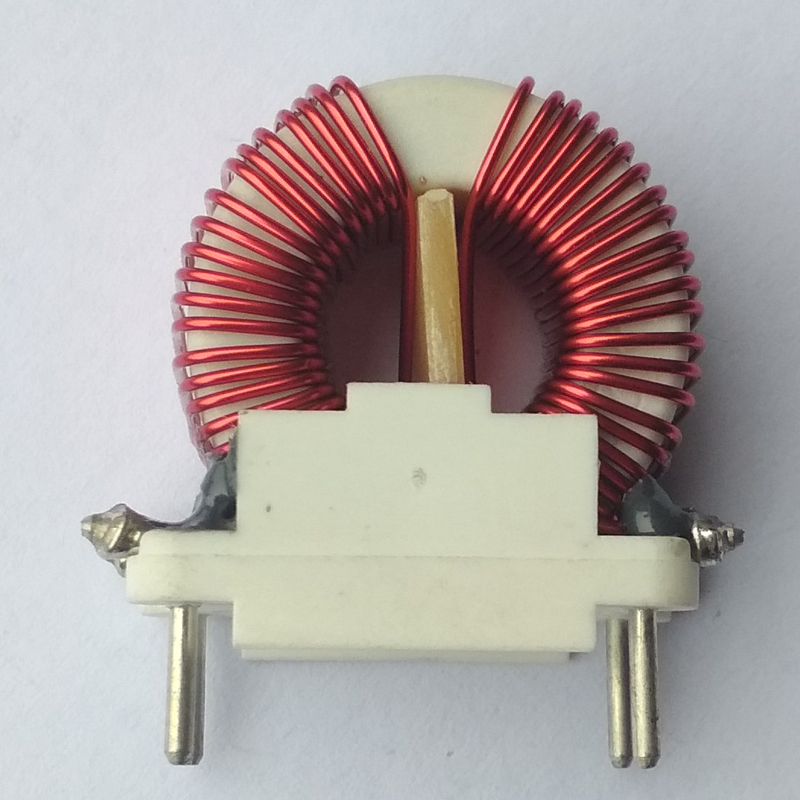

Because mn-Zn ferrites generally have high permeability, large grains, compact structure and are often black. Generally, Ni-Zn ferrites have low permeability, fine grains, porous structure and often brown, especially when the sintering temperature is low in the production process. According to these characteristics, we can distinguish them visually. In places where the light is brighter, if the color of ferrite is black and there is a dazzling sparkle, then the core is manganese-zinc ferrite; if you see that the ferrite is brown, the luster is dim, and the particles are not dazzling, the core is nickel-zinc ferrite. Visual method is a relatively rough method, which can be mastered after a certain amount of practice. Magnetic ring inductance ordering.

2. Test method

This method is reliable, but it needs some testing instruments, such as high resistance meter, high frequency Q meter and so on.

The above is the introduction of the difference between Manganese Zinc and Nickel Zinc of ferrite magnetic ring inductors. if you want to know more about inductors, please feel free to contact us.

You May Like

Read more news

Video

Specializing in the production of various types of color ring inductors, beaded inductors, vertical inductors, tripod inductors, patch inductors, bar inductors, common mode coils, high-frequency transformers and other magnetic components.

Post time: Feb-23-2022