Custom inductor manufacturer tells you

What is the composition of chip resistors? Today, the inductor manufacturer will explain it to you.

Base material

The substrate data of chip resistors are taken from 96% al2O3 ceramics. In addition to good electrical insulation, the substrate should also have excellent thermal conductivity at high temperature. The motor has the characteristics of mechanical strength and so on. In addition, the substrate is required to be flat and marked correctly. The standard of complete protection resistance. The electrode paste is printed in place.

Resistive film

The resistivity paste with a certain resistivity is printed on the ceramic substrate and then sintered. Ruthenium dioxide is used alone in resistance ointment.

Maintenance film

In order to maintain the resistor, it is important to cover the resistor film with the maintenance film. On the one hand, it plays the role of mechanical maintenance, on the other hand, the nominal insulation of the resistor avoids the fault caused by the contact between the resistance and the adjacent conductor. It can also prevent the electrode from being eroded by the electrotransfer solution in the process next to the electric transfer, resulting in the decline of the resistance function. The maintenance film is a low melting point glass paste that is printed and sintered. Chip resistor co., Ltd.

Electrode

In order to ensure the existence of good solderability and firmness of the resistor, a three-layer electrode structure is used separately: the interior. On the inside. External electrode. The inner electrode is the inner electrode connected with the resistor, so the electrode data should be selected, the resistance film has low contact resistance, strong compatibility with ceramic substrate, good chemical resistance and easy electroplating operation. Some are printed and sintered with silver-palladium alloy. The side layer electrode is a nickel-plated layer, also known as a wave barrier layer. Its function is to improve the heat resistance of welding and cushion the thermal shock of welding. It can also avoid the migration of silver ions to the resistance film layer and prevent the tin-lead layer of the outer electrode (also known as the solderable layer) from corroding the inner electrode. Its function is to make the electrode have good weldability and prolong the storage life of the electrode. Some are electroplated with tin-lead alloy.

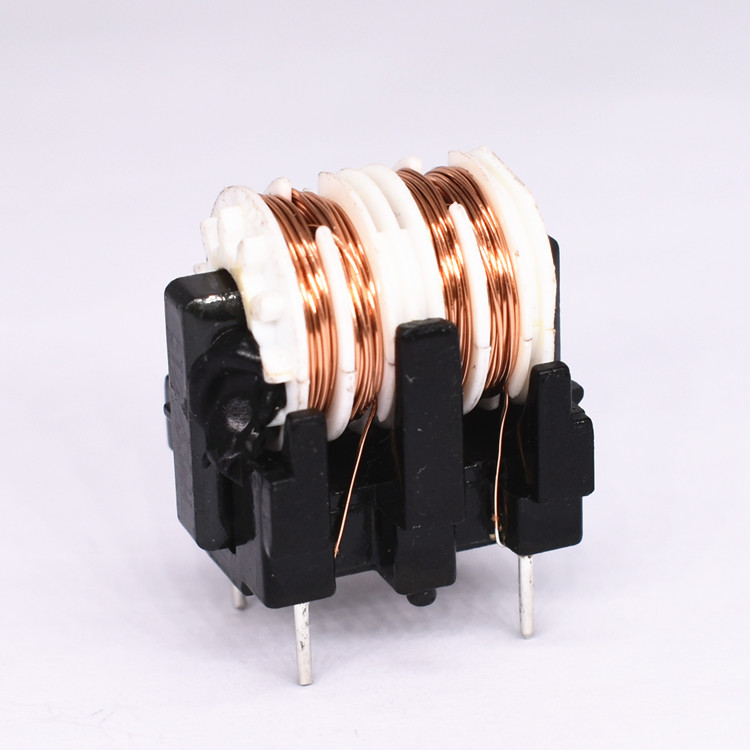

According to the resistance data, rectangular patch resistors are divided into thin film resistors and thick film resistors. Patch inductor this patch inductor is also called power inductor and high current inductor. Chip inductor is a characteristic of closed loop. The precision of thin film resistance is high and the temperature coefficient is low. The firmness is good, but the resistance range is narrow, so it is suitable for exquisite high frequency. Thick film resistors are often used in circuits.

The above is the introduction of the composition of chip resistors. If you want to know more about inductors, please feel free to contact us.

You May Like

Specializing in the production of various types of color ring inductors, beaded inductors, vertical inductors, tripod inductors, patch inductors, bar inductors, common mode coils, high-frequency transformers and other magnetic components.

Post time: Jan-19-2022